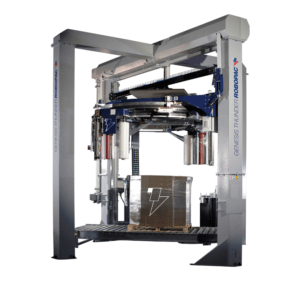

Rotary is the ideal solution for stretch film wrapping particularly unstable products. The possibility of keeping the pallet stationary or the products stable by rotating a rotating arm frequently is a necessity in the industrial field. The Rotary family is proposed as a superior quality product in an important technological field for end-of-line packaging. This machine has excellent technical and manufacturing characteristics and is the ideal choice to perform pallet wrapping reliably and efficiently.

| Arm rotation speed | rpm | 7÷12 |

| Car up-down speed | m/min | 2.5÷5.5 |

| Maximum pallet dimensions (LxW) | mm | 1400×1400 |

| Maximum product height | mm | 2000 std. 2400/2750 opt. |

| Cart type | FR, PDS, PVS | |

| Film tensioner | adjustable from the panel | |

| Pre-stretched film | n.a. (FR), fixed 250% std. (PDS), variable 150-400% (PVS) | |

| Supply voltage | V | 230V 1Ph |

| Power frequency | Hz | 50/60 |

| Maximum coil dimensions | mm | 500×300 std. / 750×300 opt. |

| Maximum coil weight | kg | 20 |

| Film thickness | μm | 17÷35 |

© 2024 Grupo Crest.

CRESTPACK is a brand managed by Eurotecsa International LLC.

All rights reserved.

Address:

224 North McColl Road, McAllen, Texas, 78501

Website development by: