The Combipacker Automatic Pick and Place Packaging Machine with placer and sealer stands out for carrying out several processes in a single piece of equipment, that is, placing cardboard type ”American suitcase”, grouping and packing products precisely and without problems, through a servomotor system, which gives agility, efficiency and precision to the process, and seals its upper tabs with adhesive or hot melt tape.

Consistency and increased productivity help improve line efficiency and reduce costs with material waste and rework.

Maximum flexibility, efficiency and speed in packaging bottles with complex geometry and caps

Developed with a friendly and intuitive interface, which makes it easy to program recipes and configure settings (set up).

Bottle distributor: ensures stability and precision in the distribution of bottles with complex geometry.

Construction with an ergonomic concept, which allows easy access for cleaning and maintenance operations, in addition to simplifying format changes (setup).

Fully automated continuous motion repetition. Eliminating human effort in repetitive motion operations.

Possibility of integration of the entire line and low need for operator intervention.

End-of-line automation, easily adaptable to a wide range of production lines

dfg

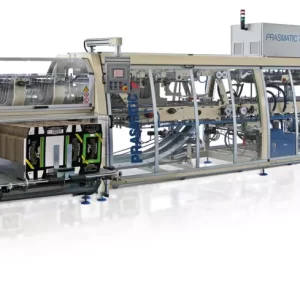

Prasmatic TC 500 600 The new range of wrappers and cartoners

© 2024 Grupo Crest.

CRESTPACK is a brand managed by Eurotecsa International LLC.

All rights reserved.

Address:

224 North McColl Road, McAllen, Texas, 78501

Website development by: